Okun Koneistuspalvelu Oy continues its significant technology investments

A special machining company in precision engineering from Outokumpu, Okun Koneistuspalvelu Oy (Oku) continues its investment programme with 1,7 million euros. Oku made its latest significant investment during the term 2017–2018, when they invested 1,5 million euros in machining equipment. The family enterprise has purposefully extended its customer branches and also strengthened its export.

According to Oku’s Managing Director Päivi Kettunen, the investment strategy of the company is based on identifying customer needs.

– We serve world-class companies with extremely high criteria for quality and security of supply. Investment decisions are not made in accordance with momentaneous economic cycles, but we aim at long-term operational development, clarified Päivi Kettunen.

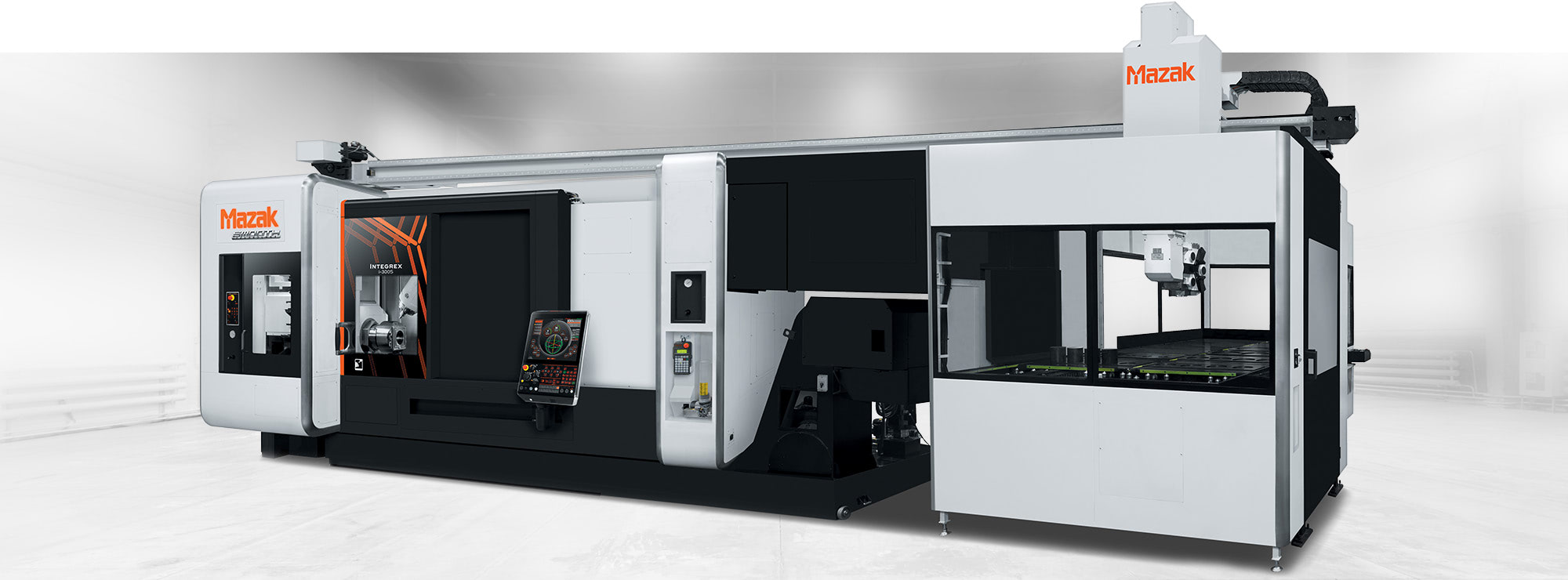

Significant investments in the current period include 2-shaft multi-axis CNC lathe and the 5-axis swiss type lathe for manufacturing small parts, produced for the first time in the Finnish precision engineering industry. The deployment of both investments will take place around the turn of the year. They will be further complemented with a 5-axis lathe centre that includes a portal robot cell. It will be deployed next spring. The investment package also includes several software acquisitions.

– The value of the machining equipment investments in 2017–2018 was ca. 1,5 million euros. The utilisation rate of the investments has quickly climbed to a good level.

Precision parts manufactured by Oku are used e.g. in aeroplanes, weapons, X-ray and laboratory equipment, paper machines, precision tools, satellites and fibre production equipment.

Automation strengthens competitiveness

Oku has two factories in Outokumpu, where precision parts are manufactured with 50 machining equipment and highly automated technology. The factories mainly operate in two manned shifts. Thanks to automation, the production also runs a third unmanned shift. The role of automation in production will be further strengthened.

– Automated technology increases competitiveness. It is a question of the ability to produce quality and to strengthen the security of supply. Thanks to automation, the position of the company in the global competitive market is enforced.

Annual recruitments

Ca. 40 professionals currently work in the special machining plant.

– The modern machine stock is one of our assets. Furthermore, we need competent employees who can get everything out of the capacity of the machines. While strengthening our technological ability, we annually recruit a few new employees.

Vanguard of North Karelia

Oku family enterprise was established in 1978 by Päivi Kettunen’s father Eero Kettunen. He serves as the Chairman of the Board of Oku. From the early phases of the company, the strategy has been to specialise in the manufacture of demanding precision engineering products.

Managing Director Kettunen is not leading the company by pursuing aggressive growth, but by strengthening technological competitiveness and investing in staff expertise.

– Everything we do is guided by customer orientation – when our customers succeed, we succeed, too.

The company currently has more than 10 direct export countries. The Managing Director sees many opportunities in the global mega trends for strengthening and extending customer branches.

– Environmental issues require new innovations, investment in sustainable development requires quality and even longer life cycle of manufactured products. The medical and well-being sector becomes stronger. These trends also represent an opportunity for Oku.

Okun Koneistuspalvelu Oy

Päivi Kettunen

Managing Director

+358 50 5630 669

paivi.kettunen@oku.fi

As investing in the future – quality, development and growth – Okun Koneistuspalvelu cooperates with North Karelia ELY Center. ELY supports Oku ‘s new technology investments through the High Technology Investment-project.